Ocean Techologies in addition has purchased an ISO 9001: 2000 quality management global common in 2003. Mainly all cable EDM manufacturers choose USD as currency and produce deliveries in accordance with the FOB deal terms. The rising demand of cord EDM and the raising amount of manufacturers has developed a healthy opposition, which has led to manufacturing of greater Wire EDM models at low prices.

Cord EDM solutions aren’t exactly new technology. The concept was actually discovered in the 1770’s by an English Scientist. It wasn’t before 1970’s that EDM was commercially produced, and in the 1980’s begun to be distributed and applied through the planet of equipment shops. Cord EDM (Electrical Discharge Machining) can be an electro thermal production process that eliminates material in an exceedingly accurate fashion by harnessing the heat of an electrical spark. Accuracy line (typically brass) is fed constantly from the spool through detail stone guides, one above and one below the work piece.

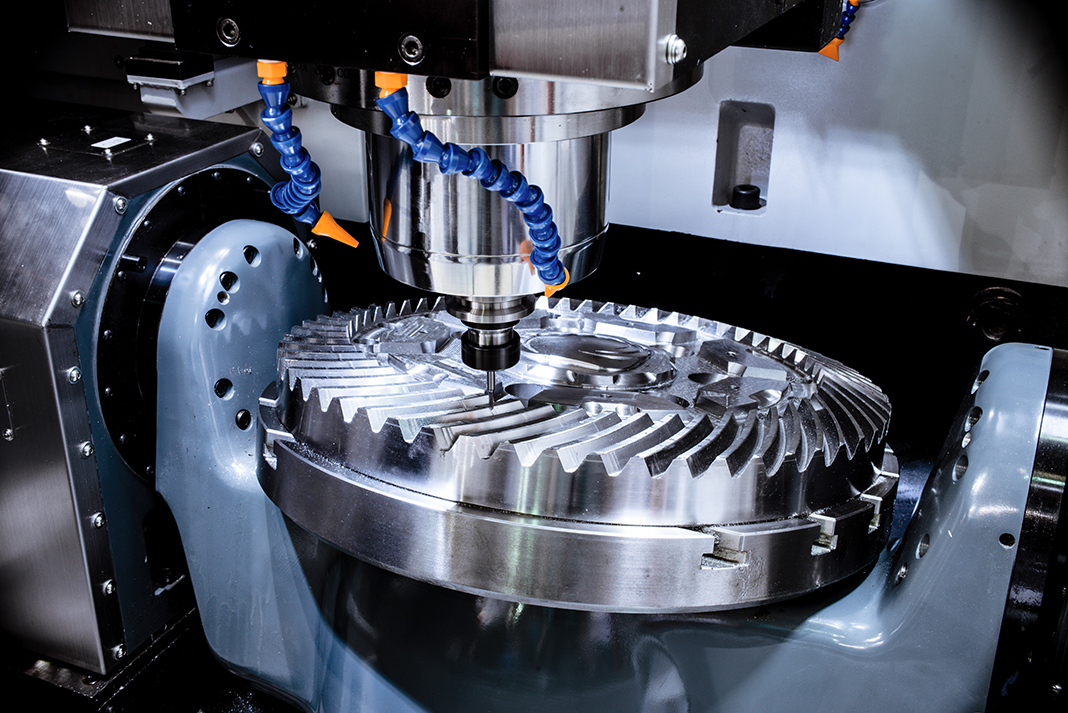

Whilst the line is provided it’s stimulated with electricity. The work part to be produced, which should be a conductive product, is grounded. The EDM machine movements the line (or the desk holding the work piece) in the trail that will be cut. Because the cord almost details the work piece, sparks commence to leap involving the cable and work bit in an exceptionally quickly, really controlled manner. The sparks are microscopic and each spark removes a really tiny piece of material CNC Lathe.

An incredible number of sparks per second are constantly eliminating material so your cord appears to be cutting through the job bit material, leaving a difference or cut course behind it slightly greater compared to the line and in whatever path the cord is programmed to undertake the work bit material. Dielectric water is fed continually over the wire and into the hole which cools and flushes out the microscopic melted particles. The applied wire, which appears microscopically pitted, is taken through to a spool or chopped into short parts to be distributed to a metal recycling facility.

The most typical line size found in EDM is.010″ diameter. The sparks themselves actually take up place, evoking the curf or reduce of the cord to be greater compared to wire itself. A.010″ length wire may leave a reduce anywhere from.0106 to.014 broad, with respect to the level of power used to really make the cut. The more energy used to help make the cut, the quicker the cord trips, and the less specific the reduce journey is.

Organizations offering cable EDM companies have many different gear and alternatives to choose from. Mitsubishi, Agie, Charmilles, and Sodik are all significant brands of wire EDM machines. A number of these models may work multiple cable sizes ranging from.0012″ length to.012″ diameter. Small line dimensions allow organizations to do micro machining and really small and complicated parts. Wire EDM is effective at producing a wide range of surface finishes. At the rough end of the scale the completes start around 250 Ra microinch ( μ” ) and by utilization of multiple cut goes can get down seriously to 4 Ra microinch ( μ” ). Several EDM products may point the wire, allowing them to make parts that have a tapered shape.

Cable EDM models will also be effective at cutting and threading the cord automatically, letting the devices to be programmed to create multiple reductions in a part without operator intervention. A hollow flow of water is shot at high stress from the top line guide to underneath, and the line is given down through that supply until the rollers in the underside head pick up the cable and beginning taking it. With most of these automatic functions created in to the models, businesses giving cord EDM services usually work their machines at night unattended on extended cuts.